Process Equipment

Gas Coolers

Gas Coolers

Application:

- Intercoolers and Aftercoolers for Centrifugal Compressors

Specifications:

- Plain tube and Plate-fin type

- Up to 300,000kg/h flows

- Pressure Drop up to 30mBar

- Conforming to TEMA RCB, ASME, AD Merkblatter, EN13445

- Materials: Copper alloy, Nickel Alloy, SS304L, SS316L, SS904L, Titanium, Super Duplex

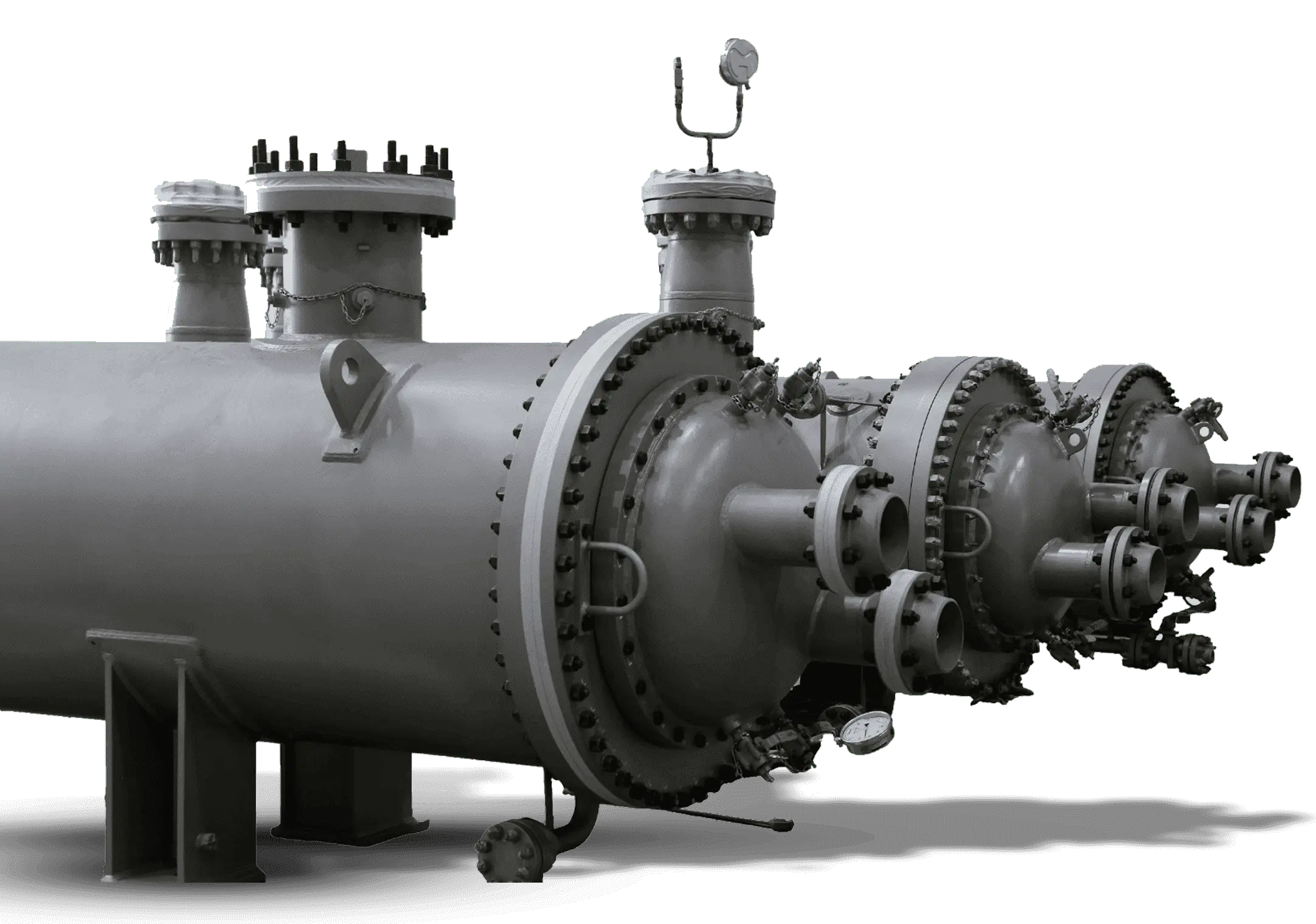

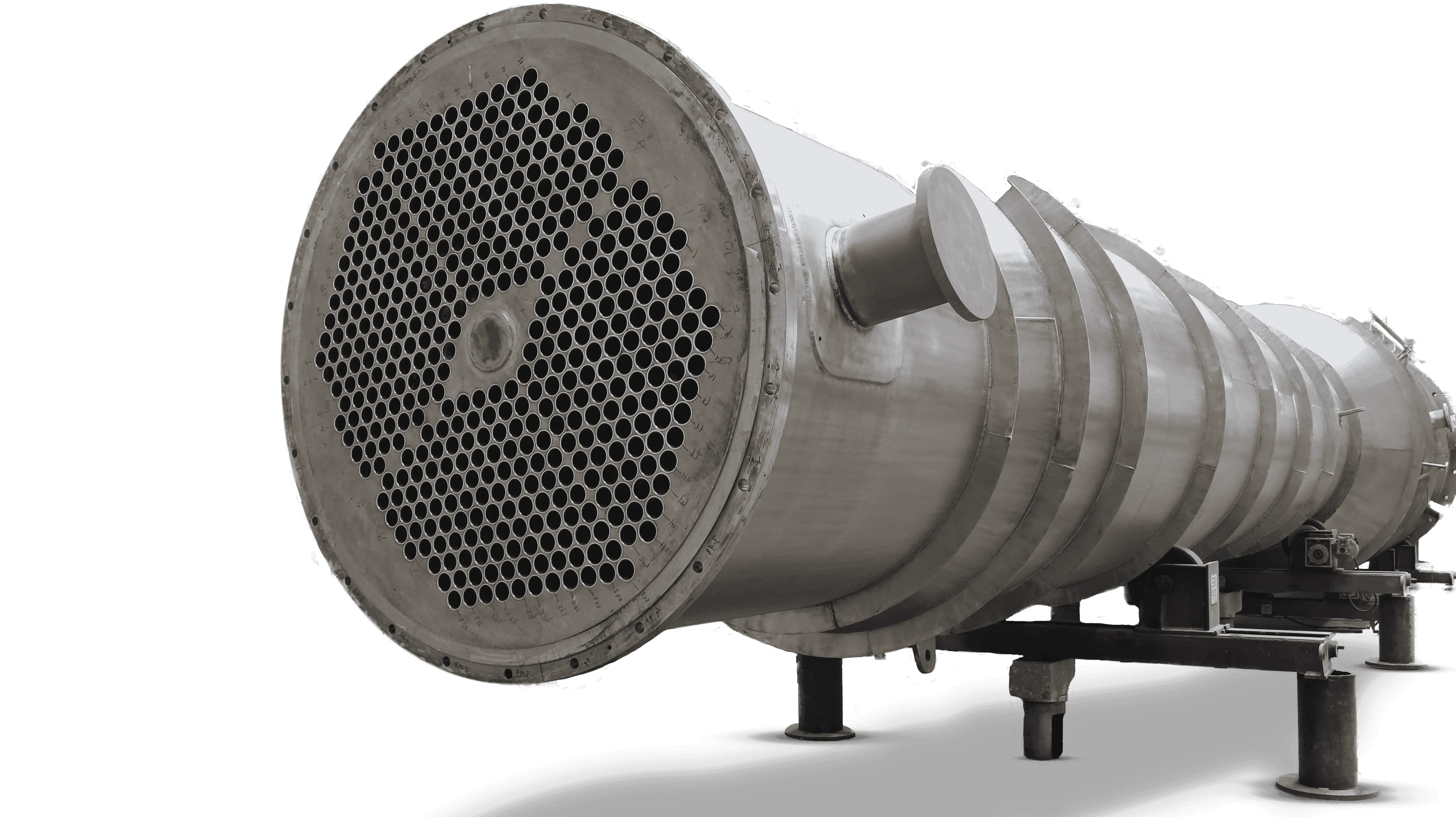

Shell & Tube Heat Exchangers

Shell & Tube Heat Exchangers

Application:

- Applications: ZLD / Desalination / Chemical / Food / Oil & Gas / Power / Pharmaceutical

Specifications:

- Optimally designed for high performance and long life using PVElite, NozzlePro and HTRI

- Conforming to TEMA RCB

- Material : Stainless Steel, Carbon Steel, Admirality Brass, Duplex, Cupro Nickel, Titanium Grade 2, Super Duplex Stainless Steel

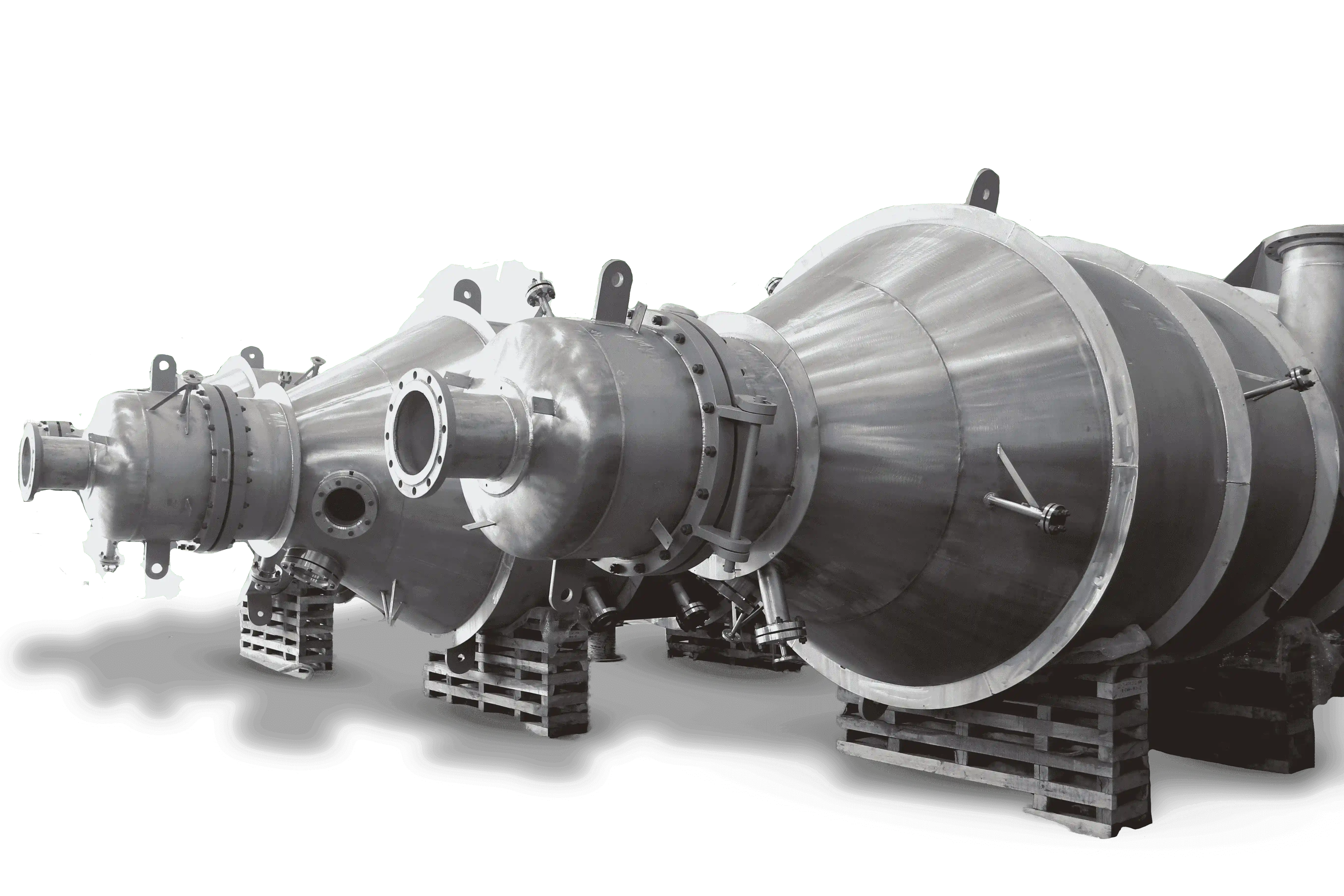

Pressure Vessels

Pressure Vessels

Application:

- For normal as well as hazardous application

Specifications:

- Optimally designed for high performance and long life using PVElite and NozzlePro software

- Diameter: Up to 4m

- Length: Up to 50m

- Weight: Up to 100Ton

- Thickness: Up to 100mm

- Materials: Incoloy 825, Super Duplex and Super Austenitic Stainless Steel, SS316, SS304, Carbon Steel

Crystallizers

Application:

- Applications: Zero Liquid Discharge and Chemicals

Specifications:

- MOC: Super Duplex and Super Austenitic Stainless Steel

Condensers

Condensers

Application:

- For Power applications

- MOC:

Specifications:

- Tubes: Admirality Brass, Titanium, Super Duplex, Super Austenitic Stainless Steel

- Shell: Carbon Steel

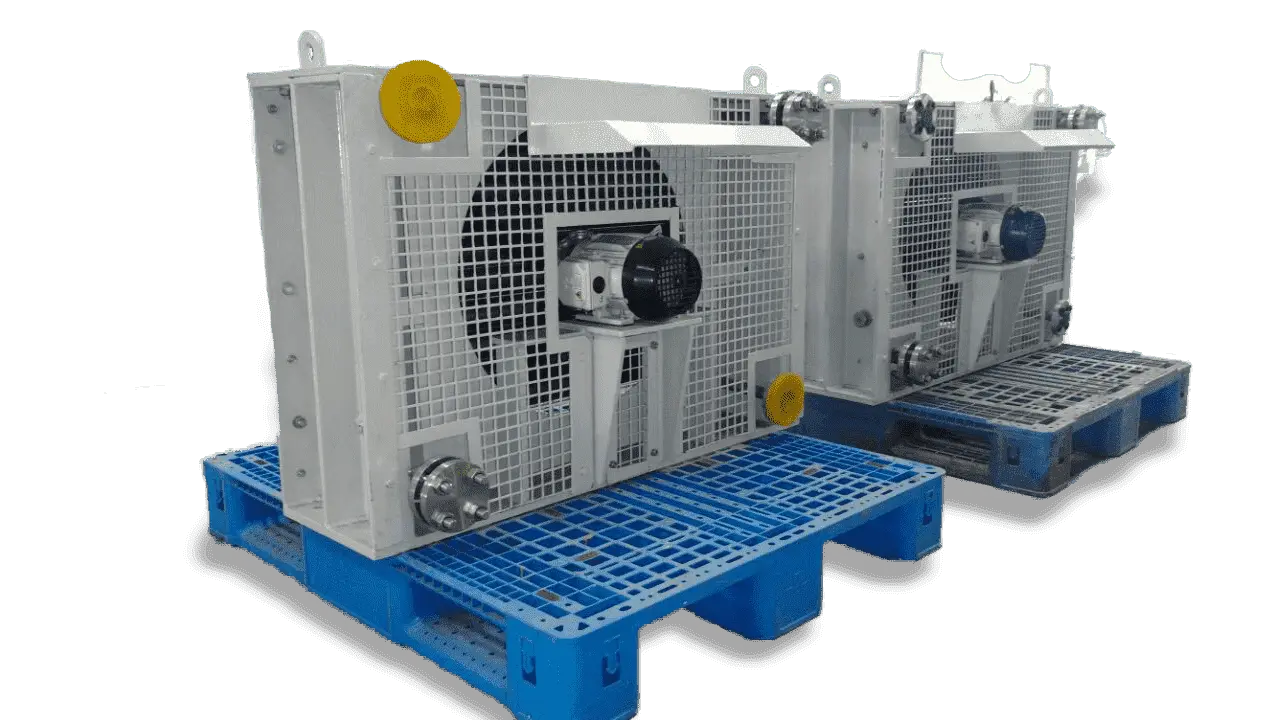

Air Coolers

Air Coolers

Application:

- For lube oil cooling, inter-cooling, after-cooling on compressors and other process applications

Specifications:

- Manufactured and tested per API 661 standard and ASME ‘U’ Stamp

- Capacity: Up to 5000kW

Volume Bottles

Volume Bottles

Application:

- For reciprocating compressors

Specifications:

- MOC: Carbon Steel and Stainless Steel